Revolutionary Photovoltaic Coatings Boost Solar Panel Efficiency by 25%

Transforming conventional solar technology, photovoltaic coatings represent one of the most significant solar panel efficiency breakthroughs of the past decade. These ultra-thin semiconductor layers convert sunlight into electricity while protecting solar cells from environmental damage, dramatically improving both performance and longevity. Applied at the nanoscale level, these advanced materials can increase energy conversion efficiency by up to 25% while reducing manufacturing costs across European solar installations.

From perovskite-based films that capture a broader spectrum of light to anti-reflective coatings that minimize energy loss, this technology is revolutionizing how we harness solar power. For European businesses and homeowners, photovoltaic coatings offer a compelling combination of improved durability, enhanced energy output, and reduced maintenance requirements – critical factors in the region’s push toward sustainable energy independence.

As climate goals become increasingly urgent across the EU, these innovative coatings are proving essential in maximizing the return on solar investments while advancing the continent’s renewable energy capabilities. Their application represents a crucial step forward in making solar power more efficient, accessible, and economically viable for both industrial and residential applications.

How Photovoltaic Coatings Transform Solar Panel Performance

The Science Behind Light-Capturing Coatings

Light-capturing coatings function through a sophisticated interplay of optical and material science principles. At their core, these innovative coatings utilize multiple layers of specially engineered materials, each designed to interact with different wavelengths of light. The primary mechanism involves anti-reflective properties that minimize light bouncing off the surface, allowing more photons to penetrate the photovoltaic cells.

These coatings typically employ nanoscale structures that create a gradual change in refractive index between air and the solar cell surface. This gradual transition significantly reduces surface reflection, much like how a moth’s eyes have evolved to absorb more light for better night vision. Some advanced coatings also incorporate light-trapping features, where incoming photons are redirected multiple times within the solar cell, increasing their chances of being absorbed.

Modern photovoltaic coatings often include self-cleaning properties through hydrophobic materials that help maintain optimal performance by preventing dust and dirt accumulation. Additionally, some coatings feature wavelength-conversion technology, which can transform otherwise unusable portions of the solar spectrum into wavelengths that solar cells can more efficiently convert into electricity.

Key Components of Modern PV Coatings

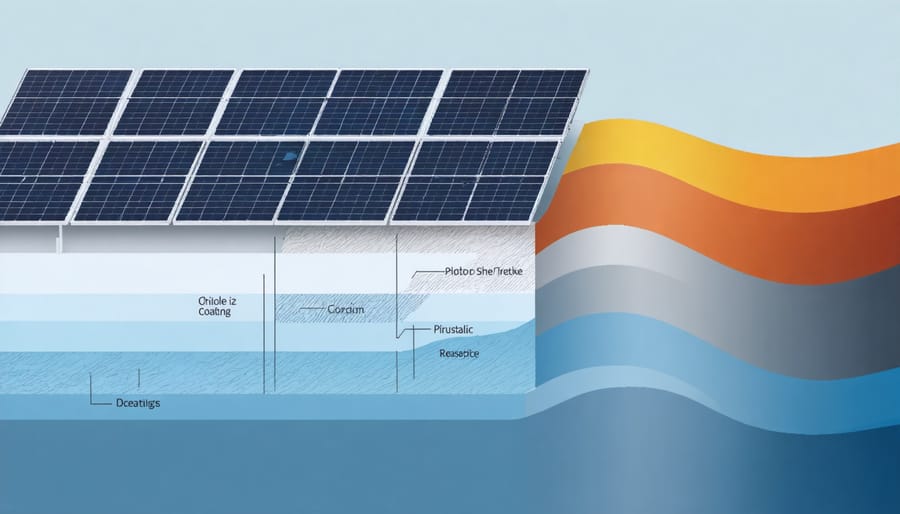

Modern photovoltaic coatings comprise several sophisticated layers, each serving a distinct purpose in maximizing solar energy conversion. At their foundation, these innovative systems build upon key solar panel materials to enhance performance and durability.

The primary components typically include an anti-reflective coating (ARC) that minimizes light reflection, allowing more sunlight to reach the photovoltaic cells. Beneath this, a transparent conductive oxide layer facilitates efficient electron transfer while maintaining optimal light transmission. A passivation layer reduces electron recombination, significantly improving cell efficiency.

Advanced PV coatings also incorporate hydrophobic layers that provide self-cleaning properties, reducing maintenance needs and ensuring consistent performance in varied European weather conditions. Some cutting-edge solutions feature thermochromic materials that adapt to temperature changes, optimizing energy absorption while preventing overheating.

The latest innovations include nano-structured coatings that can capture a broader spectrum of light and maintain high efficiency even in low-light conditions, making them particularly valuable for Northern European installations.

Latest Innovations in PV Coating Technology

Self-Cleaning Nanotechnology Coatings

Self-cleaning nanotechnology coatings represent a significant breakthrough in photovoltaic maintenance, offering a sophisticated solution to the persistent challenge of solar panel soiling. These innovative coatings utilize advanced nanomaterials that create a microscopically smooth surface, preventing dust, dirt, and other contaminants from adhering to the panel surface.

The technology works through two primary mechanisms: photocatalytic decomposition and superhydrophobic properties. When exposed to sunlight, the photocatalytic components break down organic matter, while the superhydrophobic surface causes water droplets to form perfect spheres that roll off the panel, carrying accumulated dirt with them. This process, known as the “lotus effect,” mimics the self-cleaning properties found in nature.

European manufacturers have developed particularly effective formulations that withstand harsh weather conditions while maintaining optimal transparency for maximum energy generation. These self-cleaning coatings can maintain up to 98% of a panel’s original efficiency between cleaning cycles, significantly reducing maintenance costs and water usage. For installations in dusty or urban environments, these coatings have proven to increase annual energy yield by 3-4% compared to untreated panels.

Temperature-Regulating Smart Coatings

Temperature regulation plays a crucial role in photovoltaic system efficiency, as solar panels typically experience performance losses when operating at elevated temperatures. Modern temperature-regulating smart coatings address this challenge through innovative thermal management solutions.

These advanced coatings incorporate phase-change materials and thermochromic compounds that actively respond to temperature fluctuations. During peak heat periods, the coating layer absorbs excess thermal energy, preventing it from reaching the photovoltaic cells. This stored heat is then released during cooler periods, maintaining optimal operating temperatures throughout the day.

European research institutes have developed smart coatings that can reduce panel operating temperatures by up to 20°C, resulting in a 10-15% increase in energy yield. These solutions are particularly valuable in Southern European regions, where high temperatures can significantly impact solar panel efficiency.

The latest generation of temperature-regulating coatings also features self-cleaning properties, combining thermal management with reduced maintenance requirements. This dual functionality makes them increasingly attractive for both residential and commercial installations, offering a sustainable solution for maximising solar energy production while extending system lifespan.

Anti-Reflective Innovations

Recent breakthroughs in anti-reflective coating technology have revolutionized light capture optimization for photovoltaic systems. Advanced nano-structured surfaces, inspired by moth eyes’ natural anti-reflective properties, now enable panels to capture up to 99% of incident light across broader angles and wavelength ranges.

Multi-layer interference coatings represent another significant innovation, utilizing precisely engineered thin-film stacks to minimize reflection while maximizing light transmission. These sophisticated coatings combine materials like silicon dioxide and titanium dioxide in nanometer-thick layers, creating an optimal refractive index gradient.

European research institutions have pioneered self-cleaning anti-reflective coatings that combine hydrophobic properties with enhanced light capture. These coatings not only improve initial efficiency but maintain performance longer by preventing dust and debris accumulation.

The latest development in this field involves smart adaptive coatings that respond to environmental conditions, adjusting their optical properties to optimize performance throughout the day. This technology, currently being tested in several European solar farms, shows promising results with potential efficiency gains of 3-5% over traditional anti-reflective solutions.

Real-World Benefits for European Solar Installations

Performance Improvements in Various Climates

Photovoltaic coatings demonstrate varying levels of effectiveness across Europe’s diverse climate zones, significantly impacting performance across weather conditions. In Mediterranean regions like Southern Spain and Italy, anti-reflective coatings show exceptional results, improving energy yield by up to 5% during intense summer sunshine. These coatings are particularly effective at capturing low-angle sunlight during extended daylight hours.

Northern European regions, including Scandinavia and the UK, benefit most from hydrophobic and anti-soiling coatings. These technologies help maintain efficiency during frequent rainfall and reduce snow accumulation, ensuring consistent power generation throughout the year. Testing in Denmark has shown that properly coated panels maintain up to 98% of their efficiency even during winter months.

Central European countries experience significant seasonal variations, making hybrid coating solutions particularly valuable. Recent field studies in Germany demonstrate that combined anti-reflective and self-cleaning coatings can increase annual energy yield by 3-4% compared to uncoated panels. These improvements are most notable during spring and autumn when varying weather conditions typically impact traditional panel performance.

Coastal areas across Europe benefit from specialized salt-resistant coatings, which have shown to extend panel lifespan by up to 25% while maintaining optimal performance levels in high-salinity environments.

Long-term Cost Benefits

Implementing photovoltaic coatings represents a significant upfront investment that delivers substantial long-term financial benefits. Initial installation costs typically range from €2,000 to €5,000 per 100 square meters, depending on the coating type and application method. However, these costs are often recovered within 3-5 years through enhanced energy generation and reduced maintenance expenses.

The economic advantages become particularly evident when considering the extended lifespan of solar panels with protective coatings. While uncoated panels may see efficiency drops of 20-30% over their lifetime, coated panels maintain higher performance levels, often extending their effective lifespan by 5-7 years. This translates to an additional €8,000-€12,000 in energy generation per installation.

Maintenance cost reduction is another significant benefit. Coated panels require cleaning roughly half as often as uncoated ones, reducing annual maintenance costs by 40-60%. In regions with high dust or marine salt exposure, these savings can amount to €500-€800 per year for medium-sized installations.

Insurance companies increasingly recognise the value of photovoltaic coatings, often offering reduced premiums for protected installations. Combined with various European Union sustainable energy incentives, the total financial benefit over a 25-year period typically ranges from €15,000 to €25,000 for residential installations and significantly more for commercial applications.

Implementation and Maintenance Considerations

Selecting the Right Coating Solution

Selecting the right photovoltaic coating requires careful consideration of several key factors. First, assess your climate conditions – regions with high rainfall might benefit from hydrophobic coatings, while areas with frequent dust storms may need anti-soiling solutions. Consider the panel type and material, as different coating technologies are optimised for specific substrate compositions.

Installation location also plays a crucial role. Rooftop installations in urban environments might prioritise self-cleaning properties, while ground-mounted solar farms in agricultural areas might focus on anti-reflective characteristics to maximise light absorption. Your budget and maintenance capabilities should influence the decision between single-layer and multi-layer coating systems.

European standards and local regulations must be considered when selecting coating solutions. Look for products that comply with IEC standards and carry relevant European certifications. Consider working with coating manufacturers who offer comprehensive technical support and can provide detailed performance data specific to your region.

Remember that the most expensive option isn’t always the best – focus on finding the optimal balance between cost, durability, and performance enhancement for your specific application.

Professional Application Process

The professional application of photovoltaic coatings requires careful preparation and precise execution to ensure optimal performance. Installation begins with a thorough surface assessment and cleaning of the substrate material. The surface must be completely free from dust, oils, and contaminants to achieve proper adhesion.

Temperature and humidity conditions during application are crucial factors. Most photovoltaic coatings require ambient temperatures between 10°C and 30°C and relative humidity below 85% for successful application. Professional installers use specialized equipment, including airless sprayers or roller systems, depending on the coating type and surface area.

The application process typically involves multiple layers, with specific curing times between coats. A base primer layer is often necessary to enhance adhesion, followed by the active photovoltaic coating layers. Quality control measures, including thickness monitoring and uniformity checks, are performed throughout the process.

Post-installation inspection ensures proper curing and functionality. Professional installers provide detailed documentation of the application process and specific maintenance guidelines. Regular inspections and cleaning protocols help maintain coating efficiency throughout its operational lifetime.

Maintenance Requirements

Regular maintenance of photovoltaic coatings is essential to ensure optimal performance and long-term durability. While these coatings are designed to be relatively low-maintenance, a structured care routine will maximise their efficiency and lifespan.

Quarterly visual inspections are recommended to check for any visible damage, dust accumulation, or coating deterioration. Professional cleaning should be conducted bi-annually using specialised, non-abrasive cleaning solutions to prevent coating damage. It’s important to avoid harsh chemicals or pressure washing, as these can compromise the coating’s integrity.

Performance monitoring through integrated solar management systems helps detect efficiency drops early. Annual professional assessments are advised to evaluate coating condition and address any degradation issues promptly. During winter months in northern European regions, snow removal may be necessary, but should only be performed using appropriate soft-bristled tools.

Documentation of all maintenance activities and performance metrics helps track the coating’s effectiveness over time and supports warranty compliance. For industrial installations, more frequent inspections may be required based on environmental conditions and usage patterns.

Photovoltaic coatings represent a significant leap forward in solar energy technology, offering promising solutions for increasing renewable energy adoption across Europe. As we’ve explored, these innovative coatings enhance solar panel efficiency, extend equipment lifespan, and provide substantial cost benefits over time. The technology continues to evolve rapidly, with new developments in nano-materials and smart coatings pointing towards even greater improvements in solar energy harvesting.

The future outlook for photovoltaic coatings is particularly bright in the European market, where stringent environmental regulations and ambitious climate goals drive innovation. Research indicates that the next generation of photovoltaic coatings will likely achieve even higher efficiency rates while becoming more cost-effective and environmentally friendly. We can expect to see increased integration of these coatings in building-integrated photovoltaics and novel applications in urban environments.

For homeowners and businesses considering solar energy solutions, photovoltaic coatings offer a compelling pathway to maximize their investment in renewable energy. As manufacturing processes become more refined and economies of scale take effect, the technology will become increasingly accessible to a broader market segment.

The continued development of photovoltaic coatings plays a crucial role in Europe’s transition to sustainable energy. With ongoing research and development efforts, combined with supportive policy frameworks, these technologies will undoubtedly contribute significantly to achieving the continent’s ambitious renewable energy targets while providing tangible benefits to end-users.

Leave a Reply