Real Cost Behind Grid-Scale Battery Storage: 2024 European Market Analysis

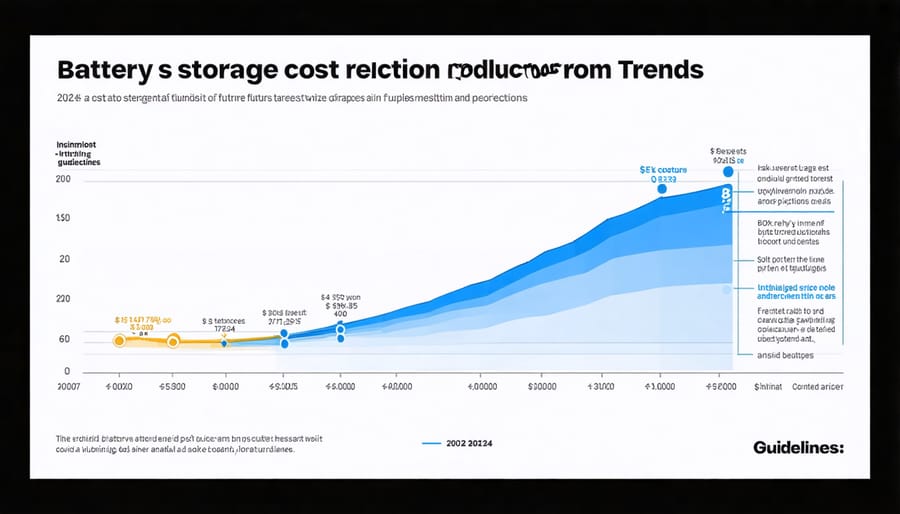

The rapidly evolving landscape of utility-scale energy storage systems has reached a critical turning point, with costs plummeting by 89% over the past decade. This dramatic shift transforms the economics of grid-scale energy storage, making it an increasingly viable solution for Europe’s renewable energy transition. Recent industry analysis reveals that lithium-ion battery storage systems now average €300-400 per kilowatt-hour installed, with projections indicating a further 40% cost reduction by 2030. For utility operators and project developers, these economics reshape the fundamental calculations of grid stabilization and peak demand management. The convergence of falling battery prices, improved technology efficiency, and supportive EU policy frameworks creates unprecedented opportunities for large-scale energy storage deployment across the continent. Understanding these cost dynamics becomes crucial as Europe accelerates its path toward a resilient, sustainable energy future.

Current Cost Components of Utility-Scale Battery Storage

Hardware and Equipment Costs

The largest component of utility-scale battery storage costs lies in the battery cells themselves, typically accounting for 30-40% of total system costs. In the European market, lithium-ion batteries currently range from €200 to €300 per kilowatt-hour (kWh), with prices continuing to decrease as manufacturing scales up and technology improves.

Power conversion systems, including inverters and transformers, represent approximately 15-20% of the total investment. These essential components, ranging from €50 to €80 per kW, convert stored DC power to grid-compatible AC power. The balance of system equipment, including racking, wiring, and containment systems, typically accounts for another 15% of costs.

Supporting infrastructure requirements add significant expenses, including grid connection equipment, monitoring systems, and safety features. These components usually comprise 20-25% of the total system cost. Climate control systems, particularly important in European weather conditions, can add €30-40 per kW to the overall cost.

For a typical 100 MW/400 MWh utility-scale installation in Europe, hardware and equipment costs currently range from €40 to €60 million. However, these costs are expected to decrease by 8-10% annually as manufacturing efficiency improves and supply chains mature. The emergence of alternative battery chemistries and standardised design approaches is also contributing to cost reductions while maintaining system reliability and performance.

Installation and Integration Expenses

Installation and integration expenses typically account for 15-25% of the total utility-scale battery storage project costs in Europe. These expenses encompass several critical components, starting with site preparation and construction, which involves groundwork, foundations, and protective enclosures for the battery systems.

Grid connection costs form a substantial portion of these expenses, including transformers, switchgear, and power conversion systems necessary for seamless integration with the existing power infrastructure. The complexity of grid connection requirements varies significantly based on location and local regulations, with costs ranging from €50,000 to €200,000 per MW of capacity.

System integration expenses cover the sophisticated control systems, energy management software, and monitoring equipment essential for optimal battery performance. These technologies ensure efficient operation and enable remote management capabilities, typically costing between €80,000 and €150,000 per installation.

Labour costs for skilled technicians and engineers during installation vary across European regions, generally ranging from €30,000 to €60,000 per MW. Project management and commissioning expenses add another layer, typically accounting for 5-8% of the total installation budget.

Additional considerations include safety systems, fire suppression equipment, and environmental protection measures, which are mandatory in most European jurisdictions. These safety-related installations usually comprise 3-5% of the total integration costs, ensuring compliance with strict European safety standards.

Operational and Maintenance Considerations

Regular Maintenance Requirements

Regular maintenance is crucial for ensuring optimal performance and longevity of utility-scale battery storage systems. The primary maintenance costs revolve around routine inspections, component replacements, and software updates for battery management systems. Typically, annual maintenance costs range from 2% to 4% of the initial capital investment.

Key maintenance activities include quarterly physical inspections of battery modules, cooling systems, and electrical connections. Temperature monitoring equipment requires calibration every six months, while safety systems need annual certification. Replacement of air filters and cooling system maintenance occurs bi-annually.

Modern lithium-ion installations benefit from predictive maintenance technologies, reducing unexpected downtime and extending system lifespan. Most European facilities employ remote monitoring systems that continuously track performance metrics and alert operators to potential issues before they escalate into costly problems.

Labour costs for maintenance teams typically account for 40-50% of the total maintenance budget, with replacement parts and consumables making up the remainder. Establishing service contracts with qualified maintenance providers can help stabilise these ongoing operational expenses while ensuring compliance with European safety standards.

Lifecycle Management

Battery degradation is a critical factor in the long-term cost assessment of utility-scale storage systems. Modern lithium-ion batteries typically experience a capacity loss of 1-2% annually under optimal conditions, leading to an expected operational lifespan of 10-15 years before requiring replacement. This degradation rate can accelerate based on factors such as cycling frequency, depth of discharge, and environmental conditions.

Proper lifecycle management strategies can significantly extend battery life and optimize investment returns. Temperature control systems, smart charging algorithms, and regular maintenance protocols play crucial roles in minimizing degradation. Many European utilities implement sophisticated battery management systems that continuously monitor cell health and adjust operational parameters accordingly.

Replacement planning typically begins when batteries reach 70-80% of their original capacity. The modular nature of modern storage systems allows for selective replacement of degraded components rather than complete system overhaul. This approach, combined with evolving battery technology and declining manufacturing costs, helps optimize lifecycle expenses. Additionally, end-of-life considerations include recycling opportunities, with European facilities achieving recovery rates of up to 95% of battery materials, contributing to both environmental sustainability and cost reduction through material reclamation.

Cost Reduction Trends and Future Projections

Technological Advancements

Recent battery cost reduction innovations have dramatically transformed the utility-scale storage landscape. Advanced lithium-ion chemistry developments have increased energy density while reducing material costs by up to 40% compared to 2015 levels. The introduction of silicon-based anodes and solid-state electrolytes has extended battery lifespan and improved safety metrics, contributing to lower lifetime operational expenses.

Manufacturing automation and economies of scale have played crucial roles in cost reduction. European gigafactories, utilizing smart manufacturing processes and artificial intelligence for quality control, have streamlined production and decreased manufacturing costs by approximately 35%. These facilities now produce batteries at a fraction of the cost compared to traditional methods.

Improved battery management systems (BMS) have enhanced operational efficiency and extended battery life cycles. Modern BMS technologies incorporate predictive maintenance capabilities and advanced thermal management, reducing degradation rates and maintenance costs. Additionally, the development of recycling technologies has created a circular economy approach, recovering valuable materials and further reducing overall costs.

The integration of artificial intelligence for optimal charge-discharge cycles and enhanced grid integration has maximized battery utilization rates, improving the return on investment for utility-scale installations. These technological advances continue to drive down costs while improving performance and reliability.

Market Scale and Manufacturing Improvements

The dramatic scaling of battery manufacturing capacity across Europe and globally has been a primary driver in reducing utility-scale storage costs. Since 2010, battery pack prices have declined by approximately 89%, largely due to economies of scale and improved production processes. Major manufacturers have established gigafactories throughout Europe, with facilities in Germany, Sweden, and Poland leading to increased production capacity and enhanced supply chain efficiency.

Manufacturing improvements have significantly impacted cost reduction through automated production lines, advanced quality control systems, and optimized material usage. These technological advancements have not only reduced production costs but also improved battery performance and longevity. The standardisation of battery modules and rack systems has further streamlined installation processes, reducing labour costs and project completion times.

The European battery industry has particularly benefited from regional partnerships and innovation clusters, fostering knowledge sharing and technological advancement. This collaborative approach has accelerated manufacturing improvements and cost reductions. Current projections indicate that utility-scale battery storage costs will continue to decrease by 8-10% annually through 2030, driven by increased production volumes and ongoing technological innovations.

Material efficiency has also played a crucial role, with manufacturers optimizing cell chemistry and reducing costly component usage without compromising performance. The development of recycling infrastructure further supports cost reduction by enabling the recovery and reuse of valuable materials, creating a more sustainable and cost-effective production cycle.

European Market Specifics and Regulations

Regional Incentives and Support Schemes

The European Union and individual member states have established robust support mechanisms to accelerate the adoption of energy storage technologies in Europe. The Innovation Fund, one of the largest funding programmes worldwide, offers significant capital support for innovative clean energy projects, including utility-scale battery storage installations. Project developers can access up to 60% of additional capital costs through this initiative.

National-level incentives vary across European countries, with Germany’s KfW Development Bank offering preferential loans with interest rates as low as 1% for large-scale storage projects. France’s energy regulatory authority CRE provides capacity market participation benefits, while Spain’s strategic projects programme PERTE ERHA allocates €1.1 billion specifically for energy storage initiatives.

Regional authorities often complement these schemes with additional support mechanisms, including simplified permitting procedures, land-use privileges, and local tax benefits. Notable examples include the Netherlands’ SDE++ scheme, which provides operational support through a contract-for-difference mechanism, and Italy’s PNRR framework, offering both capital grants and tax credits for storage projects.

Many regions also provide integrated support packages combining financial incentives with technical assistance. These packages typically include feasibility study funding, environmental impact assessment support, and grid connection assistance. The European Investment Bank further enhances these initiatives by offering project finance solutions with extended tenure and competitive rates, making utility-scale battery storage projects more financially viable across the continent.

Regulatory Framework Impact

The European regulatory landscape significantly influences the implementation costs of utility-scale battery storage systems. The EU’s Clean Energy Package and subsequent regulations have created a framework that both challenges and supports energy storage deployment. These regulations mandate specific safety standards, grid connection requirements, and environmental compliance measures that directly impact installation costs.

One of the most influential factors is the EU’s taxonomy for sustainable activities, which sets strict technical screening criteria for energy storage projects. Meeting these criteria often requires additional investment in monitoring systems and safety equipment, typically adding 5-8% to the total project costs. However, compliance also opens doors to preferential financing terms and green funding initiatives.

Grid connection regulations across European countries vary significantly, with some requiring sophisticated control systems for frequency regulation and voltage support. These technical requirements can add €50,000-150,000 per project, depending on the location and grid operator specifications. Nevertheless, these investments often pay off through enhanced grid services revenue streams.

Environmental impact assessment requirements, particularly in protected areas or densely populated regions, can extend project timelines and increase soft costs. The permitting process typically takes 6-18 months and can account for 2-4% of the total project budget. However, recent streamlining efforts in several EU member states are helping to reduce these administrative burdens.

Despite initial cost implications, the regulatory framework provides long-term benefits through standardization and clear operational guidelines. Markets with well-defined regulatory structures typically see more efficient project development cycles and better integration with existing energy infrastructure, ultimately supporting the broader transition to renewable energy systems.

The landscape of utility-scale battery storage costs in Europe continues to evolve rapidly, driven by technological advancements and increasing demand for renewable energy integration. As we’ve explored, the current costs range from €250 to €400 per kWh, with a clear downward trajectory expected in the coming years. Industry projections suggest these costs could decrease by up to 40% by 2030, making battery storage increasingly viable for grid-scale applications.

The European market stands at a pivotal point, with several factors contributing to cost optimization. Manufacturing scale-up, improved battery chemistry, and streamlined installation processes are all playing crucial roles in reducing overall system costs. Additionally, the growing emphasis on circular economy principles is expected to further drive down costs through better recycling and second-life applications.

Looking ahead, the integration of artificial intelligence and advanced management systems will likely enhance operational efficiency and extend battery lifespans, contributing to better returns on investment. The European Green Deal’s ambitious targets for carbon neutrality by 2050 will continue to support market growth and innovation in the sector.

For project developers and utilities, the key to success lies in careful planning, strategic timing of investments, and leveraging economies of scale. As the market matures, standardization of components and installation procedures will further reduce costs, making utility-scale battery storage an increasingly attractive option for grid stabilization and renewable energy integration across Europe.

Leave a Reply