How Solar Panel Supply Chains Are Transforming European Energy Security

The global energy supply chain stands at a pivotal crossroads, driven by an unprecedented energy production transformation that reshapes how we source, distribute, and consume power. From extraction and generation to final delivery, this complex network demands innovative solutions to meet rising demand while navigating sustainability challenges. European markets particularly demonstrate how modernized supply chains can enhance energy security, reduce carbon footprints, and optimize resource allocation across borders. As interconnected grids evolve and renewable technologies mature, supply chain efficiency becomes increasingly critical for maintaining reliable energy access and achieving climate goals. This intricate ecosystem of suppliers, technologies, and infrastructure requires careful orchestration to ensure seamless energy delivery while adapting to rapid market changes and emerging environmental regulations. Understanding these dynamics is essential for stakeholders seeking to optimize their energy operations and contribute to a more sustainable future.

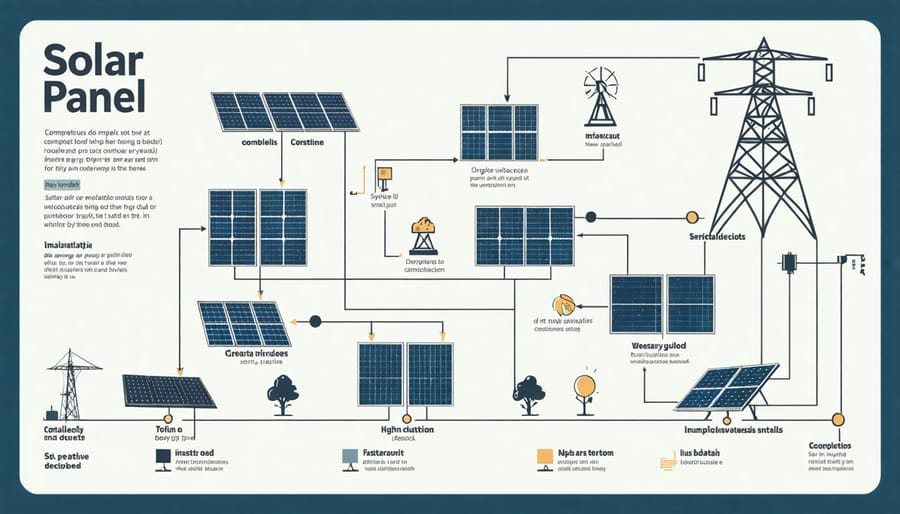

The Core Components of Solar Energy Supply Chains

Raw Materials and Component Manufacturing

The foundation of today’s solar energy supply chain lies in the careful sourcing and processing of critical raw materials. Silicon remains the primary component for advanced solar panel technology, with high-grade polysilicon production concentrated in key European manufacturing hubs. Battery storage systems rely heavily on lithium, cobalt, and nickel, with sustainable sourcing becoming increasingly important for European manufacturers.

Component manufacturing involves precise processes where raw silicon is transformed into wafers, cells, and complete modules. European facilities utilize automated production lines and quality control systems to ensure consistent output. The battery manufacturing sector has seen significant growth, with several gigafactories established across the continent to meet rising demand for energy storage solutions.

Recent innovations in material science have introduced more efficient alternatives, including perovskite solar cells and solid-state batteries. These developments are reshaping manufacturing processes while reducing dependency on rare earth materials. European manufacturers are particularly focused on implementing circular economy principles, ensuring materials can be effectively recycled and reused throughout the supply chain.

Distribution Networks and Storage Solutions

Distribution networks form the backbone of modern energy supply chains, encompassing sophisticated pipeline systems, electrical grids, and transportation infrastructure. In Europe, these networks are increasingly adapting to accommodate renewable energy sources, with smart grid technologies enabling bi-directional power flows and real-time demand management.

Storage solutions play a crucial role in maintaining supply chain stability, particularly for renewable energy integration. Contemporary options include large-scale battery facilities, pumped hydroelectric storage, and emerging technologies like hydrogen storage systems. These solutions help balance supply and demand fluctuations while ensuring consistent energy delivery to end-users.

The European Union has invested significantly in expanding and modernizing its energy distribution infrastructure, focusing on cross-border interconnections and regional energy hubs. This enhancement of distribution networks supports the continent’s energy security goals while facilitating the transition to sustainable energy sources.

Storage facilities are strategically positioned throughout the supply chain, from production sites to consumption points, creating a resilient network that can respond to varying demand patterns and potential supply disruptions. This integrated approach to distribution and storage helps maintain system reliability while supporting the growing share of renewable energy in the European power mix.

Supply Chain Challenges in Solar Energy Transition

Material Sourcing Dependencies

The energy supply chain heavily relies on critical raw materials, with their availability and accessibility significantly impacting the sector’s sustainability and efficiency. Europe’s transition to renewable energy has highlighted the importance of securing reliable material sources, particularly for solar panels, wind turbines, and energy storage systems.

Key materials like silicon, lithium, cobalt, and rare earth elements play crucial roles in energy technologies. Silicon remains fundamental for photovoltaic cells, while lithium and cobalt are essential for battery storage systems. The geographical concentration of these resources in specific regions creates inherent vulnerabilities in the supply chain.

Currently, China dominates the processing of many critical materials, controlling approximately 80% of rare earth element processing globally. This concentration has prompted European initiatives to diversify supply sources and establish domestic processing capabilities. The European Raw Materials Alliance (ERMA) actively works to reduce dependency on single-source suppliers and develop sustainable sourcing alternatives.

Geopolitical tensions can significantly impact material availability and pricing, as witnessed during recent global trade disputes. European businesses are increasingly focusing on circular economy practices, including recycling and material recovery, to reduce reliance on primary raw materials. Additionally, innovations in material science are enabling the development of alternative materials and more efficient use of existing resources, contributing to greater supply chain resilience.

Production Capacity Constraints

Production capacity in the energy supply chain faces several critical constraints that influence the availability and cost of renewable energy solutions. Manufacturing facilities, particularly those producing solar panels and wind turbines, often struggle to meet rapidly growing demand across European markets. This challenge is especially evident in the solar sector, where factory output must balance precision manufacturing with scale economics.

Key bottlenecks include the availability of raw materials, specialized equipment, and skilled workforce. Silicon wafer production, essential for photovoltaic cells, requires substantial investment in high-tech facilities that can take years to establish and optimize. Similarly, wind turbine manufacturing faces constraints in blade production capacity, with specialized facilities requiring significant space and precise environmental controls.

European manufacturers are actively addressing these limitations through automation and innovative production methods. However, scaling up manufacturing capacity requires careful planning to avoid quality compromises. Storage system production, particularly for large-scale batteries, faces similar challenges with limited production facilities and competition for critical materials.

To overcome these constraints, industry leaders are investing in new manufacturing facilities and developing more efficient production processes. Supply chain optimization strategies include vertical integration, strategic partnerships, and the establishment of regional manufacturing hubs. These efforts aim to increase production capacity while maintaining the high quality standards expected in the European market.

Optimization Strategies for Solar Supply Chains

Local Manufacturing Integration

European manufacturing capabilities are rapidly evolving to meet the growing demands of the renewable energy sector. The integration of local manufacturing facilities has become crucial for strengthening the energy supply chain and reducing dependency on international imports. This shift towards regional production has sparked significant investments in manufacturing infrastructure, particularly in countries like Germany, France, and Spain.

The development of domestic manufacturing capabilities extends beyond solar panel production to include essential components such as inverters, mounting systems, and energy storage solutions. This comprehensive approach to industrial solar adoption has created thousands of skilled jobs while fostering innovation and technological advancement within the European Union.

Local manufacturing integration offers several key advantages, including reduced transportation costs, shorter delivery times, and enhanced quality control. Moreover, it enables manufacturers to respond more quickly to market demands and regulatory changes, ensuring better alignment with European standards and sustainability goals.

The emergence of specialized manufacturing clusters has facilitated knowledge sharing and collaboration between industry players, leading to improved production efficiency and reduced costs. These clusters also support the development of circular economy initiatives, where waste materials from production processes are recycled or repurposed within the local supply chain network.

Smart Logistics and Inventory Management

Smart logistics and inventory management play a crucial role in optimizing the energy supply chain, particularly in Europe’s evolving renewable energy landscape. Modern supply chain management employs sophisticated digital solutions and artificial intelligence to predict demand patterns, manage stock levels, and coordinate deliveries with unprecedented accuracy.

Real-time tracking systems and Internet of Things (IoT) sensors monitor energy components throughout their journey, from manufacturing facilities to installation sites. This enhanced visibility allows supply chain managers to identify potential bottlenecks and respond proactively to disruptions, ensuring consistent supply to meet European energy demands.

Warehouse automation systems have revolutionized inventory management, utilizing robots and automated guided vehicles (AGVs) to improve efficiency and reduce human error. These systems work in tandem with advanced software platforms that provide detailed analytics on stock rotation, storage optimization, and demand forecasting.

The implementation of blockchain technology has increased transparency and traceability in the energy supply chain, enabling stakeholders to verify the authenticity of components and track their entire lifecycle. This innovation is particularly valuable in maintaining quality standards and preventing counterfeit products from entering the market.

European businesses are increasingly adopting predictive maintenance strategies, using data analytics to anticipate equipment needs and optimize maintenance schedules. This proactive approach minimizes downtime and ensures the continuous flow of energy supplies while reducing operational costs and improving overall system reliability.

Sustainable Practices and Circular Economy

The energy supply chain sector is increasingly embracing sustainable practices and circular economy principles to minimize environmental impact. Companies are implementing comprehensive recycling programs for critical components, particularly focusing on solar panels and battery systems at their end-of-life stage. These initiatives not only reduce waste but also help recover valuable materials like silicon, silver, and rare earth elements.

European energy suppliers are leading the way with innovative approaches to sustainability. Many have adopted eco-design principles that consider the entire lifecycle of energy infrastructure, from production to decommissioning. This includes using recycled materials in manufacturing, optimizing packaging to reduce waste, and implementing reverse logistics systems for efficient material recovery.

The transition to a circular economy in the energy sector is supported by strict EU regulations and voluntary industry commitments. Companies are investing in research and development to improve recycling technologies and develop more sustainable manufacturing processes. This includes water conservation initiatives, renewable energy use in production facilities, and the implementation of zero-waste policies.

Smart grid technologies and digital solutions are being deployed to optimize resource usage and reduce energy waste throughout the supply chain. These systems enable better demand forecasting, efficient storage management, and reduced transmission losses. Additionally, many organizations are partnering with local communities to create collection points for used energy components, ensuring proper disposal and recycling.

Future-Proofing Solar Supply Chains

Digital Integration and Automation

Digital transformation has revolutionized energy supply chain management, introducing smart solutions that enhance efficiency and reliability across the entire network. Modern energy supply chains leverage advanced software platforms that integrate real-time data monitoring, predictive analytics, and automated decision-making processes.

Internet of Things (IoT) sensors now monitor energy flow, equipment performance, and environmental conditions throughout the supply chain. These devices transmit critical data to centralized management systems, enabling operators to optimize distribution patterns and respond swiftly to fluctuations in energy demand or supply disruptions.

Artificial Intelligence and Machine Learning algorithms analyze vast amounts of historical and real-time data to predict maintenance needs, optimize inventory levels, and forecast energy demand patterns. This predictive capability helps European energy providers maintain optimal operational efficiency while reducing waste and unnecessary costs.

Blockchain technology is emerging as a game-changer in energy supply chain transparency and security. It enables secure tracking of energy sources, particularly important for renewable energy certification and trading. Smart contracts automate transactions and verify compliance with regulatory requirements, streamlining administrative processes.

Cloud-based platforms facilitate seamless collaboration between different stakeholders in the energy supply chain, from generators to distributors and end-users. These systems provide real-time visibility into operations, enabling better coordination and faster response times to market changes.

Automation has also transformed warehouse management and logistics, with robotics and autonomous vehicles optimizing the handling and transportation of energy-related equipment and components.

Resilience Through Diversification

Building a resilient energy supply chain requires strategic diversification across multiple dimensions. Successful organizations implement a multi-sourcing approach, establishing relationships with suppliers across different geographical regions to minimize disruption risks. This approach has become particularly crucial within the current European solar policy framework, which emphasizes supply chain security.

Key diversification strategies include developing partnerships with local manufacturers while maintaining connections with established international suppliers. This hybrid approach ensures consistent component availability while supporting regional economic growth. Companies are increasingly investing in warehouse networks strategically positioned across Europe, creating buffer zones that can respond quickly to demand fluctuations.

Another vital aspect is technological diversification. Forward-thinking organizations maintain flexibility by working with various solar technology types and specifications, enabling them to adapt when specific components become scarce. This includes maintaining relationships with suppliers of both traditional and emerging solar technologies.

Risk management through digital transformation plays a crucial role in supply chain resilience. Implementation of advanced tracking systems, predictive analytics, and real-time monitoring helps organizations anticipate and respond to potential disruptions before they impact operations. These digital tools enable better inventory management and more accurate demand forecasting, essential for maintaining steady supply in an evolving market.

Creating redundancy in critical supply chain elements, while carefully balancing cost implications, ensures continuous operations even during unexpected challenges. This comprehensive approach to diversification strengthens the entire energy supply ecosystem, making it more adaptable to change and more capable of sustained growth.

The optimization of solar energy supply chains plays a pivotal role in accelerating Europe’s transition to renewable energy. From raw material sourcing to end-user installation, each component of the supply chain contributes to the overall success and efficiency of solar energy projects. By addressing key challenges through innovative solutions, implementing robust quality control measures, and embracing digital transformation, businesses and homeowners can achieve more reliable and cost-effective solar installations. The future of solar energy depends heavily on maintaining resilient supply chains that can adapt to market demands while supporting sustainability goals. As Europe continues its journey toward renewable energy leadership, optimized supply chains will remain fundamental to making solar energy more accessible, affordable, and efficient for all stakeholders. Understanding and managing these supply chain dynamics is crucial for anyone looking to participate in the solar energy revolution.

Leave a Reply