Battery Recycling Demystified: The Step-by-Step Process

Uncover the hidden potential in powering a sustainable future through an in-depth look at the recycling solar batteries process. This comprehensive flowchart breaks down the intricate steps involved in transforming end-of-life batteries into valuable resources, showcasing the innovative strides being made by European industry leaders. From collection and sorting to material recovery and repurposing, each stage plays a crucial role in closing the loop on clean energy. Join us as we illuminate the path to a greener tomorrow, one battery at a time.

Battery Collection

Residential Battery Collection

For European homeowners, battery recycling is made convenient through curbside pickup and drop-off locations. Many local authorities offer regular collection of used batteries alongside other recyclables, making it easy to dispose of them responsibly. Simply place your batteries in a clear plastic bag on top of your recycling bin on the designated collection day. Alternatively, you can bring your batteries to designated drop-off points, which are often located at supermarkets, shopping centers, and local waste management facilities. These collection hubs ensure that your batteries are safely transported to specialized recycling centers. By taking advantage of these accessible options, you actively contribute to reducing waste, conserving resources, and supporting a circular economy. Proper battery disposal also prevents potential environmental and health hazards associated with improper handling. As a responsible homeowner, utilizing these convenient collection methods is a simple yet impactful way to engage in sustainable practices and promote a greener future for Europe.

Commercial & Industrial Battery Collection

For businesses and industries, battery recycling is a vital part of responsible waste management. Many commercial recycling services offer convenient collection options tailored to the needs of enterprises. These may include on-site pick-up, provision of specialized containers, and even training for staff on proper battery sorting and storage. By working with a reputable recycling partner, companies can ensure their used batteries are safely collected and processed in compliance with environmental regulations. This not only helps protect the environment but also demonstrates a commitment to sustainability that can enhance a business’s reputation. Whether a small office or a large industrial facility, every organization can contribute to the circular economy by implementing an effective battery recycling program.

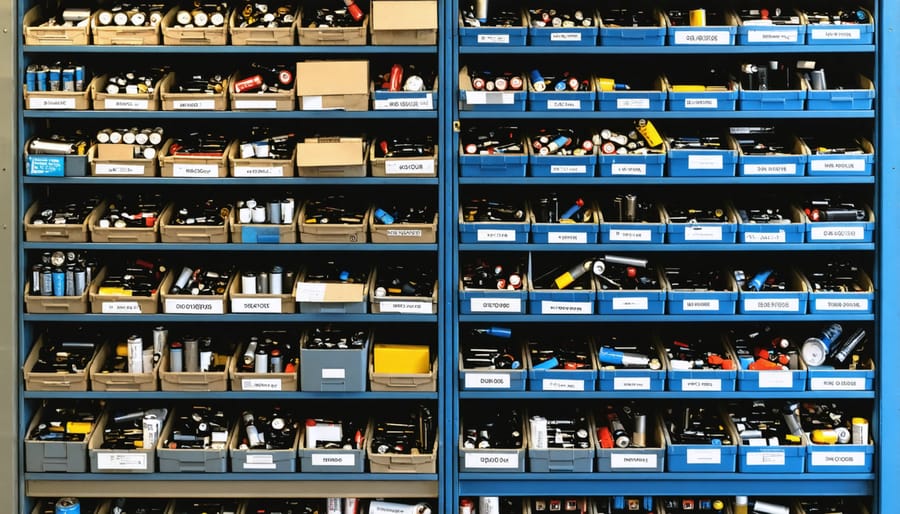

Battery Sorting & Classification

Once collected, batteries are sorted and classified based on their chemistry type to ensure proper recycling. This critical step enables the recovery of valuable materials while preventing contamination. Sorting typically involves a combination of manual and automated processes.

Visual inspection by trained personnel separates batteries by size, shape, and labeling. Damaged or leaking batteries are isolated for safe handling. Automated systems, such as optical sorters and X-ray machines, further categorize batteries by their chemical composition, like lithium-ion, lead-acid, or nickel-cadmium.

Magnetic separators remove batteries containing iron, while eddy current separators target non-ferrous metals. Advanced spectroscopic techniques, including Raman and XRF, provide precise identification of battery chemistry.

Proper sorting is essential for maximizing resource recovery and ensuring the safety of subsequent recycling processes. For example, lithium-ion batteries are directed to specialized facilities capable of handling their complex recycling needs, while lead-acid batteries follow a well-established recycling path.

Innovations in battery sorting, such as AI-powered robotics and machine learning algorithms, continually improve the accuracy and efficiency of this vital stage. By investing in state-of-the-art sorting technologies, European recyclers can enhance the sustainability and profitability of their operations while contributing to the circular economy. As the demand for batteries grows in sectors like electric vehicles and renewable energy storage, effective sorting and classification become increasingly crucial. Through rigorous sorting, Europe’s battery recycling industry is poised to recover more materials, reduce waste, and support the transition to a greener future.

Battery Dismantling

The battery dismantling process is a crucial step in the recycling lifecycle, enabling the efficient recovery of valuable materials. This stage involves both manual and mechanical processes to break down batteries into their component parts. Manual dismantling is often used for larger batteries, such as those found in electric vehicles, where skilled technicians carefully disassemble the battery packs, modules, and cells. They follow strict safety protocols to prevent short-circuits and ensure proper handling of potentially hazardous materials.

Mechanical dismantling, on the other hand, is more commonly employed for smaller consumer batteries. This process utilizes specialized equipment like shredders, hammermills, and rotary separators to break down batteries into smaller fragments. The mechanical action separates the various components, such as metal casings, electrodes, and plastics, based on their physical properties. Advanced sorting technologies, including magnetic separators and eddy current separators, further refine the material streams.

Throughout the dismantling process, great care is taken to contain any hazardous substances and minimize environmental impact. Dust collection systems and air filtration units are used to capture particulate matter, while sealed chambers prevent the release of toxic gases. The importance of proper battery dismantling cannot be overstated, as it sets the stage for the successful recovery of critical materials and contributes to overall battery sustainability efforts in Europe’s growing solar energy sector. By efficiently breaking down batteries into their constituent parts, recyclers can maximize resource recovery and minimize waste, furthering the region’s transition to a cleaner, more sustainable energy future.

Material Extraction & Purification

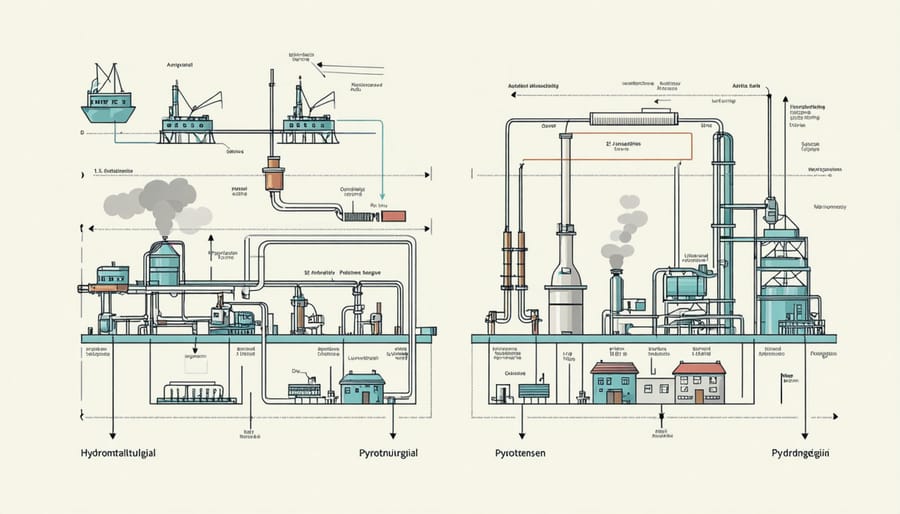

Hydrometallurgical Processes

Hydrometallurgical processes involve the extraction of valuable metals from spent batteries using aqueous solutions. This innovative approach offers a sustainable and efficient way to recover materials like lithium, cobalt, and nickel. The process typically begins with the mechanical separation of battery components, followed by the leaching of metals using acids or bases. Through a series of chemical reactions, the desired metals are selectively extracted from the solution. Techniques such as solvent extraction, precipitation, and electrowinning are then employed to purify and recover the metals in their usable forms. Hydrometallurgical methods have gained popularity in Europe due to their lower energy consumption, reduced environmental impact, and ability to handle a wide range of battery chemistries compared to traditional pyrometallurgical processes. As the demand for clean energy solutions grows, advancements in hydrometallurgical battery recycling will play a crucial role in ensuring a sustainable supply of critical materials for the European market.

Pyrometallurgical Processes

Pyrometallurgical processes involve the use of high-temperature furnaces to extract valuable metals from spent batteries. These processes typically begin with a smelting step, where the batteries are heated to temperatures exceeding 1,000°C. At these extreme temperatures, the organic components of the batteries, such as plastics and electrolytes, are burned off, leaving behind a molten mixture of metals.

The molten metals then undergo a series of refining steps to separate and purify the desired materials, such as cobalt, nickel, and copper. One common refining method is the use of selective oxidation, where the molten mixture is exposed to oxygen-rich air. This causes some metals to oxidize and form a slag layer, which can be skimmed off the surface, leaving behind a more purified metal alloy.

Another key aspect of pyrometallurgical processing is the recovery of lithium. As lithium has a lower melting point than other battery metals, it can be selectively evaporated and condensed during the smelting process. The lithium-rich vapor is then collected and further refined to produce high-purity lithium compounds.

While pyrometallurgical processes are effective at recovering valuable metals, they do have some drawbacks. The high energy consumption and potential for hazardous emissions are concerns that must be addressed through proper engineering controls and emission management systems. Despite these challenges, pyrometallurgical processing remains a crucial step in repurposing used batteries and ensuring a sustainable future for the battery industry.

Conclusion

In conclusion, the battery recycling process flowchart provides a clear overview of the key steps involved in recovering valuable materials from spent batteries. From collection and sorting to mechanical and hydrometallurgical treatments, each stage plays a crucial role in maximizing resource recovery and minimizing environmental impact. As Europe accelerates its transition to clean energy and electric transportation, efficient battery recycling will be essential to ensure a sustainable and circular economy. By closing the loop on battery materials, we can reduce our reliance on raw material imports, lower carbon emissions, and create new economic opportunities. As the demand for energy storage continues to grow, investing in robust battery recycling infrastructure and technologies will be vital to meeting our environmental goals and securing a greener future for generations to come.

Leave a Reply