Solar-Powered Industrial Fans: The Smart Way to Cut Factory Energy Costs

Revolutionizing industrial ventilation, solar-powered industrial machines like high-capacity fans are transforming European manufacturing facilities with sustainable, cost-effective cooling solutions. These innovative systems harness abundant solar energy to power robust ventilation systems, delivering up to 70% reduction in operational energy costs while maintaining optimal working conditions.

Modern solar-powered industrial fans integrate advanced photovoltaic technology with smart control systems, ensuring consistent performance even during varying weather conditions. The combination of high-efficiency motors, precision-engineered blades, and sophisticated power management systems enables these units to deliver industrial-grade airflow while operating entirely off-grid or with minimal grid dependency.

For facility managers seeking sustainable ventilation solutions, these systems offer compelling advantages: zero operational energy costs, minimal maintenance requirements, and significant carbon footprint reduction. The latest generation of solar industrial fans demonstrates how renewable energy can effectively meet demanding industrial requirements while advancing European sustainability goals in manufacturing and warehousing operations.

How Solar-Powered Industrial Fans Work

Core Components

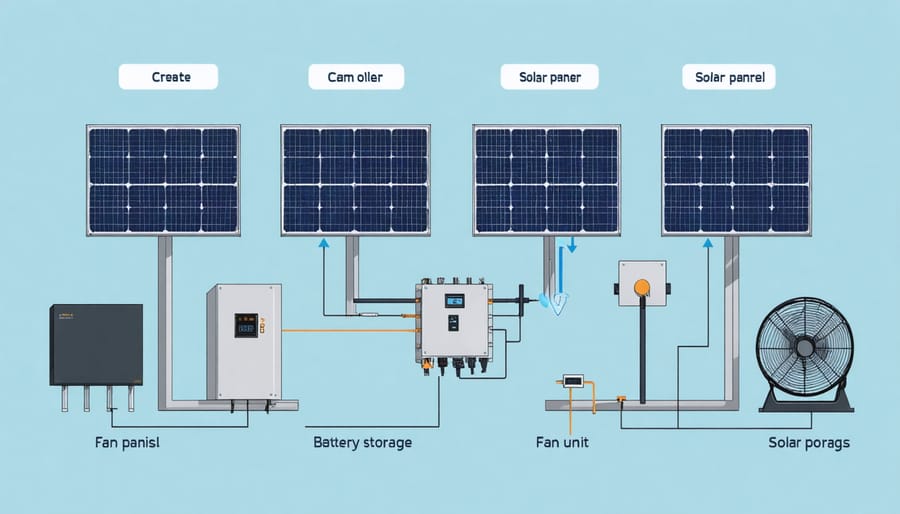

A solar-powered industrial fan system consists of four essential components working in harmony to deliver reliable ventilation. At its heart are high-efficiency photovoltaic panels, which form the foundation of modern industrial solar solutions. These panels, typically monocrystalline or polycrystalline, convert sunlight into direct current (DC) electricity with conversion rates reaching up to 23% in premium models.

The charge controller serves as the system’s brain, regulating voltage and current flow between panels, batteries, and the fan motor. Advanced MPPT (Maximum Power Point Tracking) controllers optimize energy harvest throughout the day, ensuring stable operation even under variable weather conditions.

Energy storage comes in the form of deep-cycle batteries, predominantly lithium-ion or advanced lead-acid types, which store excess daytime power for night-time operation. Modern battery systems feature sophisticated battery management systems (BMS) that extend battery life and maintain optimal performance.

The fan mechanism itself comprises an efficient DC motor, precisely engineered blades, and a robust housing designed for industrial environments. Contemporary models incorporate brushless DC motors, which offer superior efficiency and reduced maintenance requirements. The blade design balances airflow capacity with energy consumption, while variable speed controls allow for adaptive ventilation based on environmental conditions or specific facility requirements.

Integration with Existing Systems

Integrating solar-powered industrial fans into existing ventilation systems requires careful planning but offers remarkable flexibility. Modern solar fan systems are designed with compatibility in mind, making industrial solar energy integration straightforward for most facilities.

The process typically begins with an assessment of current ventilation infrastructure. Retrofit solutions often include adaptor plates and universal mounting brackets that enable solar fans to connect seamlessly with existing ductwork and ventilation openings. Hybrid controllers can be installed to manage the transition between solar and grid power, ensuring continuous operation during varying weather conditions.

For optimal integration, facilities can implement a phased approach, gradually replacing or supplementing conventional fans with solar alternatives. This method allows for thorough testing and adjustment of the system while minimizing disruption to operations. Modern solar fan systems also come with smart monitoring capabilities that can integrate with building management systems (BMS), providing real-time performance data and automated control options.

When properly integrated, these systems can operate alongside traditional ventilation equipment, creating a robust and efficient hybrid solution that maximizes energy savings while maintaining reliable performance.

Key Benefits for European Industries

Energy Cost Reduction

Implementing solar-powered industrial fans can significantly reduce operational energy costs, offering an attractive return on investment for European businesses. A typical industrial fan operating 8 hours daily consumes approximately 2,400 kWh annually. By switching to solar power, facilities can save between €360 to €600 per fan yearly, depending on local electricity rates and solar conditions.

The initial investment for a solar-powered industrial fan system, including installation and supporting infrastructure, typically ranges from €2,500 to €4,000. With current European energy prices and available renewable energy incentives, most installations achieve complete ROI within 4-6 years.

Additional cost benefits include reduced maintenance expenses due to fewer moving parts and the ability to operate independently from the grid during peak rate hours. Many European businesses report 30-40% lower overall ventilation costs after transitioning to solar-powered systems. When factoring in potential carbon tax savings and government incentives for sustainable technologies, the financial advantages become even more compelling.

For maximum cost efficiency, businesses should consider implementing smart controllers that optimize fan operation based on solar availability and ventilation needs.

Environmental Impact

Solar-powered industrial fans significantly contribute to reducing carbon emissions in industrial and commercial settings. By harnessing Europe’s solar potential, these systems can eliminate up to 90% of the carbon footprint associated with traditional electric ventilation systems. A typical industrial fan operating on solar power can prevent approximately 2.5 tonnes of CO2 emissions annually, equivalent to planting 40 trees.

These sustainable ventilation solutions align perfectly with the EU’s carbon reduction targets and environmental regulations. They help facilities meet the requirements of the European Green Deal and contribute to the EU’s goal of achieving climate neutrality by 2050. Furthermore, businesses implementing solar-powered fans often qualify for green energy incentives and environmental certifications, enhancing their sustainability credentials.

The environmental benefits extend beyond carbon reduction. Solar-powered fans eliminate the need for complex electrical infrastructure, reducing material waste and environmental impact during installation. They also contribute to lowering urban heat island effects and improving air quality in industrial areas, making them an integral part of sustainable industrial development.

Operational Benefits

Solar powered industrial fans offer remarkable operational advantages, combining robust performance with minimal maintenance requirements. These systems operate at peak efficiency during the sunniest hours, precisely when ventilation needs are highest, ensuring optimal workplace comfort. The direct-drive mechanisms eliminate the need for belt replacements and reduce mechanical wear, significantly lowering maintenance costs.

The smart controllers in modern solar fan systems automatically adjust fan speeds based on available sunlight, optimizing energy utilization throughout the day. With no operational electricity costs and only annual cleaning and bearing checks required, these fans provide exceptional long-term value. The absence of complex electrical connections also means fewer potential failure points, resulting in enhanced reliability and reduced downtime.

For European facilities, these systems align perfectly with sustainability goals while delivering consistent performance across diverse seasonal conditions.

Implementation Considerations

Site Assessment

A thorough site assessment is crucial for the successful implementation of solar-powered industrial fans. Start by evaluating the available roof or ground space for solar panel installation, ensuring it receives optimal sunlight exposure throughout the day. Consider potential shading from nearby structures, trees, or equipment that could impact solar panel efficiency.

The facility’s structural integrity must be assessed to support both the solar array and fan systems. This includes roof loading capacity, mounting possibilities, and existing electrical infrastructure. Wind patterns and local climate conditions play vital roles in determining fan placement and solar panel orientation.

Examine your facility’s ventilation requirements, including air volume needs, temperature control targets, and operating hours. This information helps determine the appropriate fan size and required solar capacity. Consider seasonal variations in both solar availability and cooling demands.

Local building regulations and permit requirements should be reviewed early in the planning phase. Energy consumption patterns and peak usage times must align with solar generation periods for maximum efficiency. A professional assessment can identify potential challenges and opportunities specific to your facility, ensuring optimal system design and performance.

Installation Requirements

For successful installation of a solar-powered industrial fan system, proper site assessment and technical preparation are essential. The primary requirements include a south-facing installation area with unobstructed sun exposure, ensuring maximum solar panel efficiency. The mounting surface must support both the fan unit (typically weighing 15-25 kg) and solar panels (approximately 20 kg per panel).

The electrical specifications typically call for a 24V or 48V DC system, with panel capacity ranging from 100W to 500W depending on fan size and operational needs. Installation requires professional mounting brackets, UV-resistant cabling, and a charge controller to regulate power flow.

Structural considerations include roof load capacity assessment, wind resistance factors, and appropriate weatherproofing measures. For optimal performance, the installation area should maintain an ambient temperature between -20°C and 45°C.

Essential safety components include surge protection devices, proper grounding systems, and emergency shut-off mechanisms. Local building regulations and electrical codes must be followed, with particular attention to European CE certification requirements and regional renewable energy installation standards.

Professional installation by certified technicians is strongly recommended to ensure system longevity and warranty validity.

Maintenance Guidelines

To ensure optimal performance and longevity of your solar-powered industrial fan, implement a systematic maintenance routine. Clean the solar panels quarterly using non-abrasive materials and specialised solar panel cleaning solutions. Remove dust, leaves, and debris that might reduce energy absorption efficiency.

Inspect the fan blades monthly for dust accumulation and clean them with a damp cloth. Check blade alignment and tighten any loose mounting hardware. The motor bearings should be lubricated annually according to manufacturer specifications to prevent wear and maintain smooth operation.

Monitor the battery system’s performance and check connections every six months. Clean battery terminals and ensure proper ventilation around the battery housing. Replace batteries according to manufacturer recommendations, typically every 5-7 years.

Verify the solar charge controller settings bi-annually and inspect all electrical connections for signs of wear or corrosion. Keep a maintenance log to track performance patterns and schedule preventive care. During winter months in northern Europe, ensure snow and ice don’t accumulate on the panels, as this can significantly impact energy generation.

Consider arranging annual professional inspections to maintain warranty validity and ensure all components function at peak efficiency.

Case Studies: Success Stories

A leading automotive parts manufacturer in Stuttgart, Germany, achieved remarkable success by implementing a solar-powered ventilation system across their 5,000-square-meter facility. The installation of 12 industrial-grade solar fans resulted in a 35% reduction in cooling costs during the first year of operation, while significantly improving worker comfort and productivity.

In Barcelona, Spain, a textile manufacturing plant integrated eight solar-powered industrial fans into their existing ventilation infrastructure. The hybrid system maintains optimal temperature control during peak production hours, reducing their carbon footprint by 28 tonnes annually. The project’s success has inspired neighbouring facilities to adopt similar sustainable solutions.

A noteworthy implementation comes from a Dutch greenhouse complex near Rotterdam, where solar-powered fans maintain ideal growing conditions year-round. The facility’s smart control system adjusts fan speeds based on temperature and humidity levels, resulting in 40% energy savings compared to traditional ventilation methods. The installation paid for itself within three years through reduced operational costs.

In Northern Italy, a food processing facility installed a comprehensive solar fan network that operates independently during daylight hours. The system includes energy storage capabilities, ensuring consistent ventilation even during cloudy periods. This installation demonstrates how modern solar fan technology can provide reliable industrial ventilation while adhering to strict food safety regulations.

These success stories showcase how European industries are effectively combining solar power with ventilation needs, achieving both environmental and economic benefits while maintaining operational excellence.

Solar-powered industrial fans represent a significant step forward in sustainable facility management, offering European businesses a practical solution to reduce energy costs while advancing their environmental commitments. Throughout this guide, we’ve explored how these innovative systems combine reliable ventilation with clean energy technology, delivering both immediate and long-term benefits for industrial operations.

The key advantages we’ve discussed – from substantial energy savings and reduced carbon emissions to minimal maintenance requirements and enhanced operational reliability – make solar-powered fans an attractive investment for forward-thinking businesses. With European energy prices continuing to rise and environmental regulations becoming more stringent, the timing has never been better to consider this sustainable upgrade.

For businesses ready to explore solar fan implementation, we recommend starting with a comprehensive site assessment to determine optimal placement and system specifications. Working with qualified solar installation experts who understand local regulations and available incentives will ensure a smooth transition. Remember that many European nations offer generous subsidies for industrial solar installations, making the initial investment more manageable.

Take the first step towards sustainable ventilation by requesting a professional consultation and energy assessment today.

Leave a Reply